Structural Detailing in BIM: Rebar and Steel Connections

- PV Digital

- 1 day ago

- 5 min read

In any of the construction projects, designs don’t just get built by drawings themselves. One has to clearly explain what steel goes where, how it is fixed, and how everything fits together. Such work is what we call as structural detailing.

So, what structural detailing does is that it simply turns engineering designs into clear instructions, which is easy to adapt to for site teams and fabricators to actually follow.

Why structural detailing matters

Structural detailing tells the construction team:

Where reinforcement bars go inside concrete

How steel beams and columns are connected

What sizes, lengths, and quantities are required

With unclear details, there are high chance of mistakes happening on-site, leading to delays, rework, and higher costs.

How BIM changes structural detailing

Earlier, teams worked with many separate drawings. This is often confused because:

One drawing didn’t match another

Changes were missed

Clashes were found too late

With adaptation of Building Information Modeling (BIM), everyone works on one shared digital model.

This shared model helps:

Reduce mistakes

Improve accuracy

Keep all teams aligned

All kinds of people working in the project, whether contractors, fabricators, detailers, or engineers, all refer to the same information throughout the project.

Because of this, BIM-based structural detailing has become integral, not optional, for today’s industrial, commercial and infrastructural projects.

Structural detailing. What is it?

Structural detailing is the process of preparing clear drawings and models that show:

What reinforcement or steel is needed

Where it should be placed

How it should be connected

This information tells about fabrication and on-site construction.

What information does structural detailing include?

Structural detailing typically shows:

Sizes of reinforcement bars

Spacing between bars

Lengths, bends, and hooks

Identification marks for each bar

Steel connection details and materials

This information becomes the base for:

reinforcement work

Steel fabrication

Site execution

BIM in structural detailing

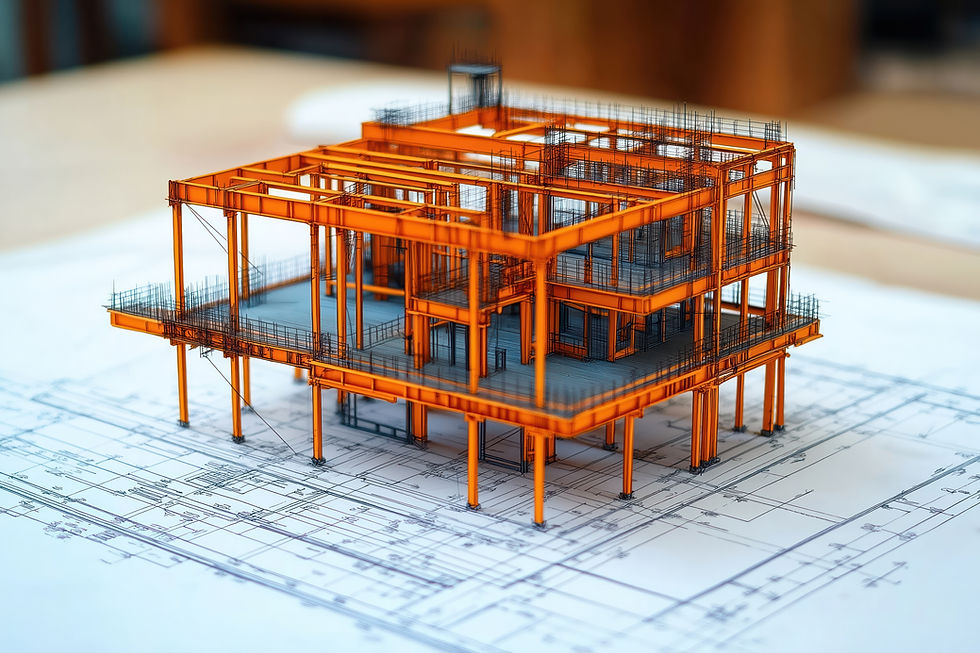

Working in flat drawings was the traditional way; now, teams use BIM to view structural detailing in 3D. This makes it much easier to understand how parts connect and fix problems before construction begins.

Post this, it's easy to:

See how elements fit together

Find clashes early

Generate drawings and schedules automatically

As a result, BIM-based detailing helps:

Reduce errors

Improve accuracy

Minimize material waste

Speed up construction

BIM-based detailing, in this way, provides a complete 3D visual representation of beams, columns, trusses, stairs, and steel connections.

Rebar modeling in BIM

Rebar modeling shows where steel rods go inside concrete parts using a 3D computer model.

Instead of guessing from drawings, teams can clearly see:

Bar sizes

Spacing

Placement

Why this helps

Fewer mistakes on site

Better coordination with other systems

Clearer instructions for fabrication

Benefits of rebar modeling

Using BIM for rebar modeling helps:

Detect problems early

Reduce congestion inside concrete

Generate bar bending schedules automatically

save time in drafting and checking

This makes reinforcement work seamless and more reliable.

Rebar modeling using Autodesk Revit

Revit allows engineers and detailers to place reinforcement directly into the 3D model.

It supports:

standard rebar shapes

automatic schedules

consistent documentation

Big projects such as bridges and tall buildings might need a few additional tools for dealing with tightly packed reinforcement.

Steel connection detailing in BIM

Steel connection detailing tells how different steel members are connected.

In BIM, every steel element is modeled accurately.

This helps fabricators and site teams clearly understand:

How connections are made

What materials are needed

How components are assembled

Why BIM is useful for steel connections

BIM helps by:

Showing steel connections in 3D

Detecting clashes with other building systems

Generating fabrication and erection drawings automatically

This way, accuracy is improved, and errors are reduced during fabrication and installation.

Best practices for steel connection detailing

Good steel detailing focuses on:

Clear communication between teams

Correct measurements and standards

Careful checking before fabrication

Detailers must:

Follow building codes

Coordinate with fabricators

Consider site conditions

With the correct way, on-site risks are reduced and better construction outcomes are supported.

Bar Bending Schedule (BBS) in Structural Detailing

A bar-bending schedule is a list that tells fabricators:

Which bars are needed

Their sizes and shapes

How many are required

In BIM, this schedule is created automatically from the model, which:

Reduces manual errors

Keeps drawings and schedules consistent

Comparison: Traditional vs BIM-Based Structural Detailing

Aspect | Traditional Detailing | Structural Detailing BIM |

Coordination | Manual | Model-based |

Clash Detection | Late-stage | Early-stage |

Accuracy | Drawing-dependent | Data-driven |

Documentation | Manual updates | Automated |

Error Risk | High | Significantly reduced |

Linking detailing with fabrication

When structural detailing is connected directly to fabrication:

Data flows smoothly

Machines receive accurate information

Errors caused by manual data transfer are reduced

This creates a clear path from design to construction.

Clash checking in structural detailing

Clash checking means finding conflicts before construction starts.

For instance:

Reinforcement clashing with pipes

Steel beams get in the way of air ducts

With BIM tools, the tasks become easy. The teams can solve problems on the computer before construction starts, rather than fixing them at the site. In this manner, they save their time and also money.

Bill of Materials (BOM) in BIM-Based Detailing

For the project, this is the needed materials list.

BIM helps generate accurate BOMs by pulling data directly from the model, which supports:

Procurement planning

Cost control

Reduced material waste

Quality assurance in structural detailing

Quality assurance checks the following:

drawings are correct

codes are followed

mistakes are caught early

Using BIM makes checking easier through automated reviews and coordinated models.

Documentation in structural detailing

Structural detailing produces documents such as:

fabrication drawings

erection drawings

rebar schedules

steel connection details

Such documents guide construction from start to finish.

Why choose PrimaVerse for structural BIM services?

PrimaVerse provides structural BIM services that help deliver:

accurate detailing

clear documentation

better coordination

fabrication-ready outputs

This helps turn designs into on-site construction without confusion. Our executive team even delivers specialized rebar modeling and steel detailing services.

FAQs

1. Define structural detailing?

Structural detailing describes the way a structure will actually be built. It shows where reinforcement and steel elements go and how they are connected.

2. How does BIM improve detailing?

A shared 3D model is used for error reduction, improvement in coordination and keeping the entire team aligned.

3. What is rebar modeling?

Rebar modeling shows reinforcement bars in 3D so placement is clear and accurate.

4. Why is reinforcement detailing important?

It ensures concrete structures are strong, safe, and durable.

5. How does BIM help steel connections?

It allows precise modeling, clash detection, and accurate drawings.

6. What is a BBS?

A Bar Bending Schedule lists all reinforcement details needed for fabrication.

7. What is clash checking?

It finds conflicts between systems before construction starts.

8. What is BOM generation?

BOM generation creates the entire list of materials that are needed for the project.

9. Role of quality assurance. Is it important?

With the help of quality assurance, you can easily prevent errors and there's a surety of safety and compliance.

10. How do BIM services help large projects?

They improve coordination, reduce mistakes, and speed up construction.

Comments