Mastering Mechanical Drafting for Improved Designs

- Marketing PrimaVerse

- Oct 31, 2025

- 4 min read

Mechanical design drafting is a critical skill in engineering and manufacturing. It involves creating detailed technical drawings that communicate how mechanical components and systems should be built. Mastering this craft can significantly improve the quality and efficiency of your designs, leading to better products and smoother production processes.

Understanding the fundamentals of mechanical design drafting helps engineers, designers, and manufacturers collaborate effectively. This article explores key aspects of mechanical design drafting, practical tips for improvement, and the types of drafting techniques used in the industry.

The Importance of Mechanical Design Drafting in Engineering

Mechanical design drafting serves as the blueprint for manufacturing mechanical parts and assemblies. It translates complex ideas into clear, standardized drawings that everyone involved in the production process can understand. Without precise drafting, errors and misinterpretations can lead to costly delays and product failures.

Some of the main reasons why mechanical design drafting is essential include:

Clear Communication: Drafts provide a universal language for engineers, machinists, and fabricators.

Accuracy: Detailed drawings ensure parts fit together correctly and function as intended.

Documentation: Drafts serve as official records for design specifications and revisions.

Quality Control: They help identify potential design flaws before production begins.

By mastering mechanical design drafting, professionals can reduce errors, save time, and improve overall product quality.

Key Principles of Effective Mechanical Design Drafting

To create effective mechanical design drafts, it is important to follow certain principles that enhance clarity and precision. Here are some practical guidelines:

1. Use Standardized Symbols and Notations

Mechanical design drafting relies on industry standards such as ANSI, ISO, or ASME. Using standardized symbols for dimensions, tolerances, and materials ensures that drawings are universally understood.

2. Maintain Proper Scale and Proportions

Drawings should be to scale, meaning the size of the drawing corresponds proportionally to the actual object. This helps in visualizing the part and verifying dimensions.

3. Include All Necessary Views

A single view is rarely enough. Use multiple views such as front, top, side, and sectional views to fully describe the geometry of the part.

4. Dimension Clearly and Concisely

Dimensions should be placed outside the object outline and avoid clutter. Use leader lines and extension lines to connect dimensions to the relevant features.

5. Specify Materials and Finishes

Indicate the type of material, surface finish, and any special treatments required. This information is crucial for manufacturing and quality assurance.

6. Review and Revise Thoroughly

Double-check all measurements, notes, and symbols before finalizing the draft. Peer reviews can catch mistakes that might be overlooked.

By adhering to these principles, drafts become more reliable and easier to interpret.

What are the three types of mechanical drafting?

Mechanical drafting can be categorized into three main types, each serving a specific purpose in the design and manufacturing process:

1. Detail Drafting

Detail drafting focuses on creating individual part drawings. These include precise dimensions, materials, and manufacturing instructions. Each part is documented separately to ensure it can be produced accurately.

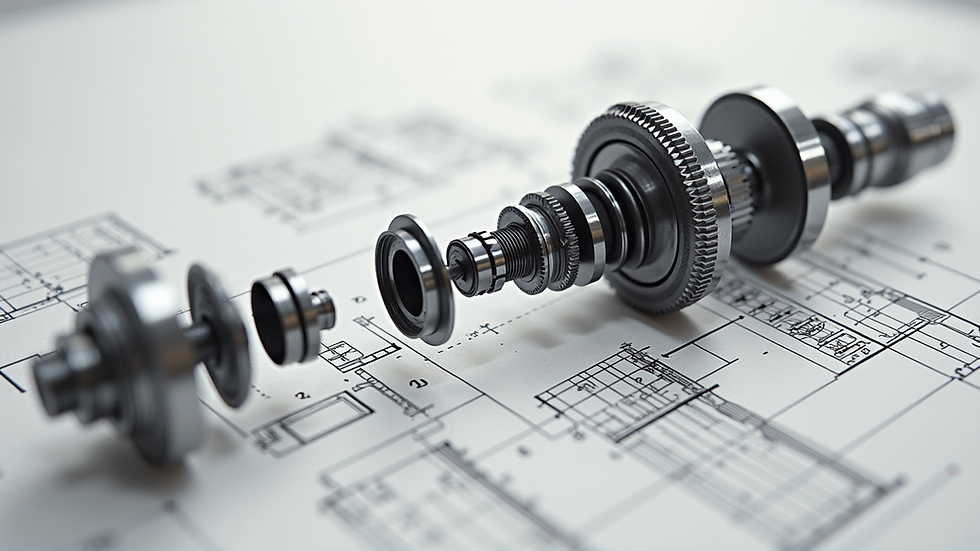

2. Assembly Drafting

Assembly drafting shows how multiple parts fit together to form a complete machine or system. It includes exploded views, assembly sequences, and references to individual part drawings.

3. Installation Drafting

Installation drafting provides instructions for installing the assembled product in its operational environment. It covers mounting details, connections, and integration with other systems.

Understanding these types helps professionals choose the right approach for their project and ensures all aspects of the design are covered.

Tools and Technologies for Modern Mechanical Design Drafting

The evolution of technology has transformed mechanical design drafting from hand-drawn sketches to sophisticated computer-aided design (CAD) systems. Here are some tools and technologies that enhance drafting efficiency and accuracy:

Computer-Aided Design (CAD) Software

CAD software like AutoCAD, SolidWorks, and CATIA allows drafters to create precise 2D and 3D models. These tools offer features such as:

Automated dimensioning

Real-time error checking

Easy revisions and version control

Simulation and analysis capabilities

3D Modeling and Visualization

3D models provide a realistic representation of parts and assemblies. They help identify design issues early and improve communication with stakeholders.

Digital Drafting Tablets and Pen Displays

These devices enable more natural drawing input and can be integrated with CAD software for enhanced productivity.

Cloud Collaboration Platforms

Cloud-based tools facilitate real-time collaboration among team members, allowing for faster feedback and decision-making.

By leveraging these technologies, professionals can produce higher-quality drafts more efficiently.

Practical Tips to Improve Your Mechanical Design Drafting Skills

Improving your mechanical design drafting skills requires practice and attention to detail. Here are actionable recommendations:

Master the Basics: Understand drafting standards, symbols, and conventions thoroughly.

Practice Regularly: Work on diverse projects to gain experience with different components and assemblies.

Use Templates and Checklists: Develop templates for common parts and checklists to ensure all details are included.

Seek Feedback: Share your drafts with peers or mentors to get constructive criticism.

Stay Updated: Keep up with the latest CAD software updates and industry standards.

Focus on Clarity: Always prioritize clear communication over artistic flair.

Learn from Real-World Examples: Study existing mechanical drawings to understand best practices.

By following these tips, you can enhance your drafting accuracy and efficiency.

Enhancing Designs with Professional Mechanical Drafting Services

For complex projects or when in-house expertise is limited, outsourcing to professional mechanical drafting services can be a smart choice. These services offer:

Expert knowledge of industry standards

Access to advanced CAD tools

Faster turnaround times

Reduced risk of errors

If you want to elevate your design process, consider partnering with a reliable provider specializing in mechanical drafting. Their expertise can help you create detailed, accurate drafts that improve manufacturing outcomes and product quality.

Moving Forward with Mechanical Design Drafting Excellence

Mastering mechanical design drafting is a journey that combines technical knowledge, practical skills, and the right tools. By understanding the principles, types, and technologies involved, you can create better designs that meet functional requirements and manufacturing constraints.

Whether you are an engineer, designer, or manufacturer, investing time in improving your drafting skills will pay off in more efficient workflows and superior products. Embrace continuous learning, leverage modern tools, and consider professional support when needed to stay ahead in the competitive world of mechanical design.

Start refining your mechanical design drafting today and watch your designs transform from concepts to reality with precision and clarity.

Have a project in mind? Contact us today and let’s build a better world together!

Comments